About Us

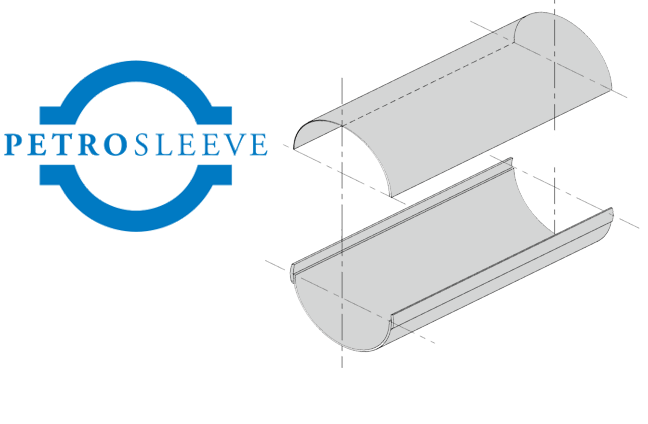

First conceived in the 1990s, the PETROSLEEVE® Pipeline Repair System is the result of many years of diverse and successful projects in pipeline integrity and pipeline construction completed by Petro-Line Upgrading Services Ltd.

The patented PETROSLEEVE® Pipeline Repair System was developed to permanently and quickly repair pipe defects without interrupting operations or requiring complex in-service welding procedures to weld to the pipeline.

History

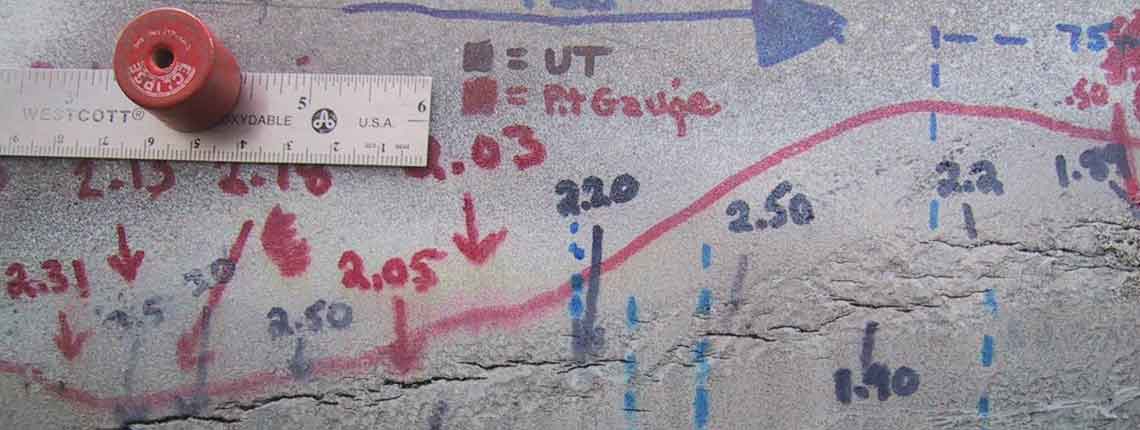

Industry required a permanent repair solution after an increased discovery of significant Stress Corrosion Cracking (SCC).

The PETROSLEEVE® was first installed in Canada. Today, with over 30,000+ PETROSLEEVE® installations worldwide, we are truly the industries gold standard in pipe repair.

- – Today – Over 30,000+ PETROSLEEVE® installations worldwide

- – PETROSLEEVE® is first used as a crack arrestor on low toughness pipeline

- – PETROSLEEVE® is installed in France

- – PETROSLEEVE® is installed in Papua New Guinea

- – PETROSLEEVE® is first used as a CP test lead contact

- – PETROSLEEVE® is installed in Australia

- – The Canadian Standards Association (CSA) recognizes the “Steel Compression Reinforcement Sleeve” repair method with the PETROSLEEVE® meeting and exceeding Z662 standard

- – PETROSLEEVE® is installed in the Dominican Republic

- – PETROSLEEVE® is installed in Mexico

- – PETROSLEEVE® installed on a through wall anomaly for testing purposes

- – PETROSLEEVE® is installed in the United States

- – DOT OPS Reviewed PETROSLEEVE® for use in United States

- – PETROSLEEVE® is installed in Canada

- – Successful full scale testing completed

- – Industry required a permanent repair solution after an increased discovery of significant Stress Corrosion Cracking (SCC)

Cost Evaluation

Using the PETROSLEEVE® Pipeline Repair System immediately reduces project costs. Alternative application options do not compete with our cost saving matrixes.

Immediate Savings: The PETROSLEEVE® offers cost savings on every installation. This is achieved in part because:

- • Repairs occur while your pipeline remains in operation

- • The immense costs of cut-out repairs are avoided

- • You will easily repair more pipeline in less time

- • PETROSLEEVE® eliminates lost production costs

- • The completed repair is permanent

- • Your repair budget is greatly extended

- • Every sleeve comes with free analysis/quality online control software

- • Free software reduces documentation costs

- • The PETROSLEEVE® exceeds code requirements

Cost and Safety Comparison: In a simple study reviewing both Cost Factor and Safety Risks inherent different methods of repairing defects, the PETROSLEEVE® clearly demonstrated immediate and cumulative project cost savings. The following cost and safety comparison studied a single defect repair on a NPS 20 pipeline. Important to note, this study excluded the enormous costs of operational shutdowns; a true benefit of using the PETROSLEEVE®.

Safety & Environment

After the installation of a PETROSLEEVE®, the pipeline owner can immediately confirm that their repair criteria has been achieved. You can have confidence in choosing the PETROSLEEVE® Pipeline Repair System as your pipeline repair method, knowing that zero failures have been reported for any installed PETROSLEEVE®.